Make Best Use Of Value: Aftermarket Construction Parts Fundamentals

Make Best Use Of Value: Aftermarket Construction Parts Fundamentals

Blog Article

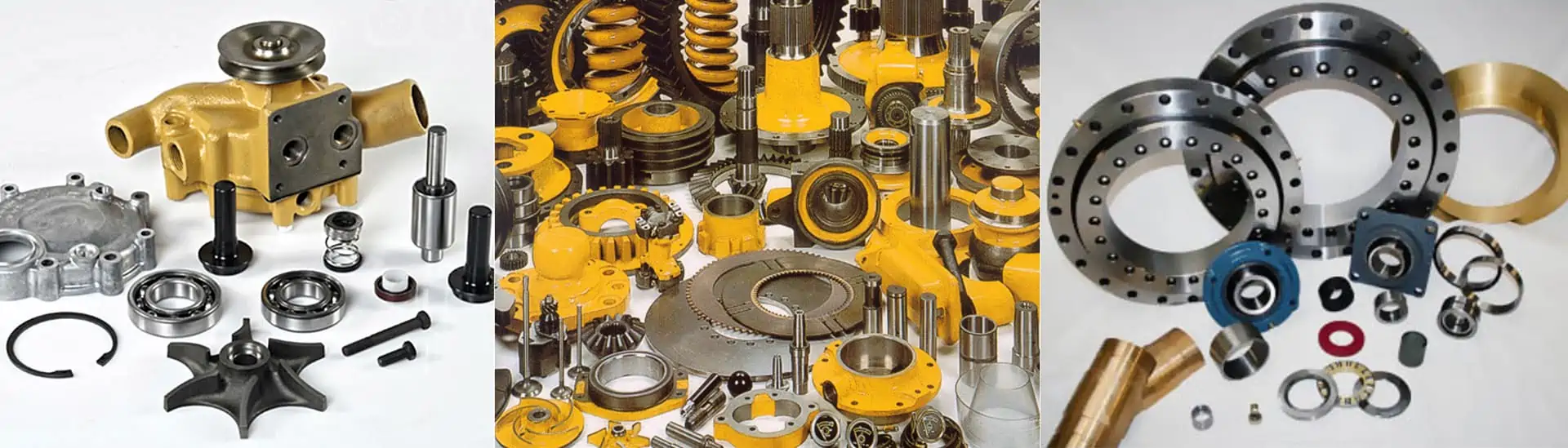

Improve Efficiency With Top-Quality Aftermarket Construction Components for Heavy Equipment

In the realm of hefty equipment operations, the quest for ideal performance is a continuous quest. One essential aspect that often plays a crucial role in accomplishing this effectiveness is the quality of aftermarket building parts used. These parts can be the unhonored heroes of equipment performance, calmly adding to smoother operations and boosted productivity. The essential lies not just in getting aftermarket parts yet in ensuring they meet the greatest standards of top quality and compatibility. As machinery maintenance needs precision and dependability, a critical strategy to selecting and including aftermarket components can make all the distinction in the globe of heavy machinery procedures.

Benefits of Using Aftermarket Building And Construction Components

These components, created by third-party manufacturers, give a more affordable option to original devices producer (OEM) parts without compromising on high quality. By choosing for aftermarket parts, hefty machinery proprietors and drivers can obtain top notch components at a fraction of the cost of OEM parts, permitting for substantial cost savings in maintenance and repair work costs.

Additionally, aftermarket building parts are easily available in the market, guaranteeing minimal downtime for equipment undertaking repair services. This quick accessibility to a large array of aftermarket parts helps expedite the repair and maintenance processes, eventually enhancing the functional effectiveness of hefty machinery. In addition, aftermarket components are frequently developed to satisfy or exceed OEM requirements, guaranteeing compatibility and performance. This compatibility guarantees that aftermarket parts effortlessly integrate with existing machinery, optimizing and promoting smooth procedures performance (aftermarket construction parts). Generally, the advantages of making use of aftermarket building components make them a beneficial selection for cost-conscious hefty machinery proprietors looking for efficient upkeep services.

Variables to Consider When Picking Parts

When selecting parts for heavy machinery maintenance and fixing, it is crucial to very carefully consider a number of key elements to make sure optimal efficiency and long life. Ensure that the aftermarket parts are compatible with the specific make and version of the hefty machinery to avoid issues such as wrong fit or functionality. By thoroughly examining these variables, you can make informed decisions when picking aftermarket components for hefty equipment maintenance and repair.

Importance of Routine Upkeep

Taking into consideration the vital role that high quality aftermarket parts play in guaranteeing ideal efficiency and long life for heavy machinery, the relevance of normal maintenance can not be overemphasized. Normal maintenance is essential for maintaining heavy machinery operating at peak effectiveness while decreasing the threat of unanticipated malfunctions. By performing routine examinations, lubricating moving components, and replacing damaged components in a prompt way, drivers can protect against costly downtime and expand the life expectancy of their equipment.

Furthermore, routine maintenance not only boosts the performance of heavy equipment however likewise adds to office security. Properly maintained equipment is much less likely to malfunction or trigger accidents, protecting both operators and spectators. Furthermore, positive maintenance methods can aid recognize potential problems before they escalate right into significant issues, conserving time and cash over time.

Enhancing Machinery Efficiency With Upgraded Components

To enhance heavy equipment performance, integrating updated parts is a tactical strategy that can dramatically enhance effectiveness and reliability. Upgraded components are created to meet greater criteria of quality and durability compared to typical OEM parts, offering enhanced efficiency capacities. By buying excellent aftermarket components, such as sophisticated hydraulic systems, strengthened tracks, or high-performance engine parts, hefty equipment drivers can experience improved functionality and expanded machinery life-span.

One key benefit of utilizing upgraded components her latest blog is the potential for enhanced performance. Upgraded elements typically include advanced innovation or materials that can handle heavier workloads, run more effectively, and require less maintenance. This enhanced efficiency can bring about greater outcome levels and lowered downtime, ultimately maximizing the total effectiveness of the machinery.

Additionally, updated components can likewise add to cost financial savings over time. While the preliminary financial investment in premium aftermarket parts might be greater, their improved sturdiness and efficiency can lead to fewer repairs and substitutes, saving both time and cash over the life expectancy of the equipment. Inevitably, enhancing machinery efficiency with upgraded components is a wise investment that can result in raised cost-effectiveness, effectiveness, and reliability.

Price Cost Savings and Long-Term Worth

Maximizing expense financial savings and long-lasting value is a crucial purpose when purchasing updated aftermarket components for hefty equipment. While the initial financial investment in top-notch aftermarket parts might seem more than choosing less costly options, the lasting advantages far surpass the ahead of time expenses. Premium aftermarket components are created to be dependable and resilient, reducing the regularity of replacements and reducing downtime for maintenance, eventually translating right into considerable cost savings with time.

Furthermore, purchasing premium aftermarket parts can improve the general performance and performance of hefty equipment, resulting in enhanced productivity and smoother procedures. By choosing aftermarket parts from reputable suppliers that stick to industry criteria, you can guarantee that your equipment runs at its ideal level, minimizing the danger of pricey repair services and unforeseen breakdowns.

Final Thought

To conclude, aftermarket building and construction components use various benefits such as cost savings, enhanced performance, and long-lasting worth. By thinking about variables like quality, compatibility, and reliability when selecting components, equipment effectiveness can be greatly enhanced. Regular maintenance and upgrades with high-grade parts are important for making certain ideal performance of heavy machinery. Generally, buying aftermarket construction parts is More about the author a wise choice for taking full advantage of performance and productivity in building procedures.

As machinery maintenance demands precision and dependability, a calculated technique to selecting and integrating aftermarket components can make all the difference in the world of hefty machinery operations. - aftermarket construction parts

These parts, produced by third-party suppliers, offer a more cost effective choice to original devices manufacturer (OEM) components without jeopardizing on top quality. By choosing for aftermarket parts, hefty equipment owners and operators can acquire high-grade parts at a portion of the expense of OEM components, allowing for significant savings in upkeep and repair work expenditures.

Upgraded parts are made to meet higher criteria of high quality and toughness compared to basic OEM parts, offering improved efficiency capabilities. By investing in high-grade aftermarket components, such as sophisticated hydraulic systems, strengthened tracks, or high-performance engine parts, heavy machinery operators can experience enhanced view capability and prolonged equipment lifespan.

Report this page